I'll get in touch with you soon!

Cake Line

Produce up to 900 cakes / h with the most flexible line for industrial cake production in the market! Use the Unifiller Multi Station and a Cake-O-Matic or Cake Station in combination with a 3m conveyor and build up your individual production line for the production of round cakes! Industrial cake production couldn’t be easier.

The Unifiller Cake Line

for highest production rates

The latest edition of our Cake Line is very easy to handle and more advanced, as the syrup spraying unit is now synchronized with the following Multi Station. Within the space of less than 6 meters only 3 people can produce up to 700 (16 cm) cakes/hour – from spraying syrup to applying the middle filling, assembling and icing of the cakes – using most efficient equipment. Adding a second depositor for icing and one more person, the capacity of this line can be increased to up to 900 cakes/h.

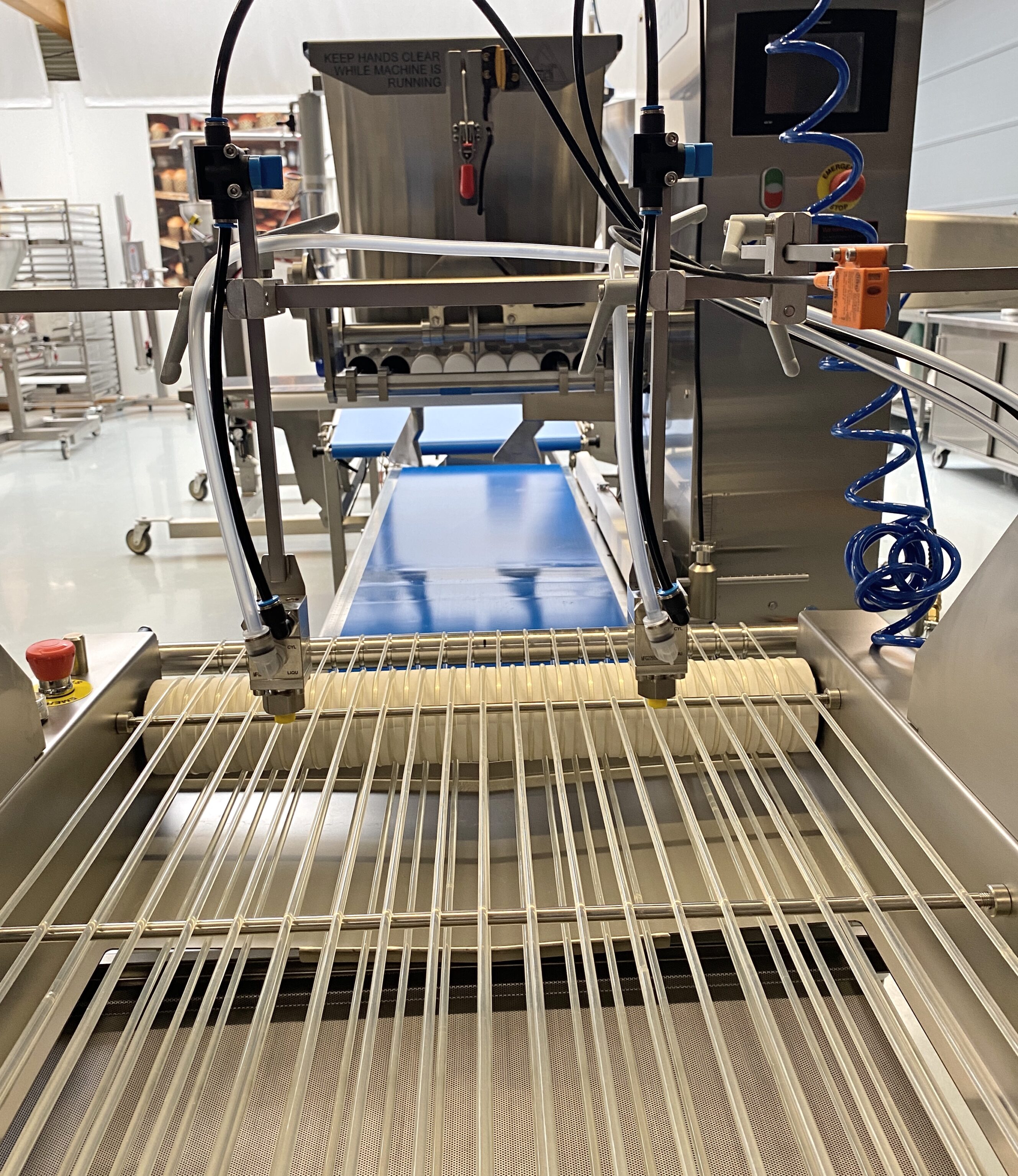

Lately we have developed a syrup sprayer, that is able to communicate with the Multi Station – whenever the Multi Station stops for applying the middle filling, the syrup sprayer stops as well. The sponges are centered on the belt of the syrup sprayer and then will be in perfect position for automated spreading of the middle filling on the Multi Station. Perfect as well for the production of rectangular layer cakes – automated detection for syrup spraying and spreading the filling makes life easy for production workers. They are mainly needed for feeding the line with sponges, assembling the cakes and icing.

Cakes with diameter 10cm – 22cm can be produced in 2 lanes on the Multi Station resulting in a higher production capacity, cakes from more than 22cm up to 30cm diameter are processed in one row.

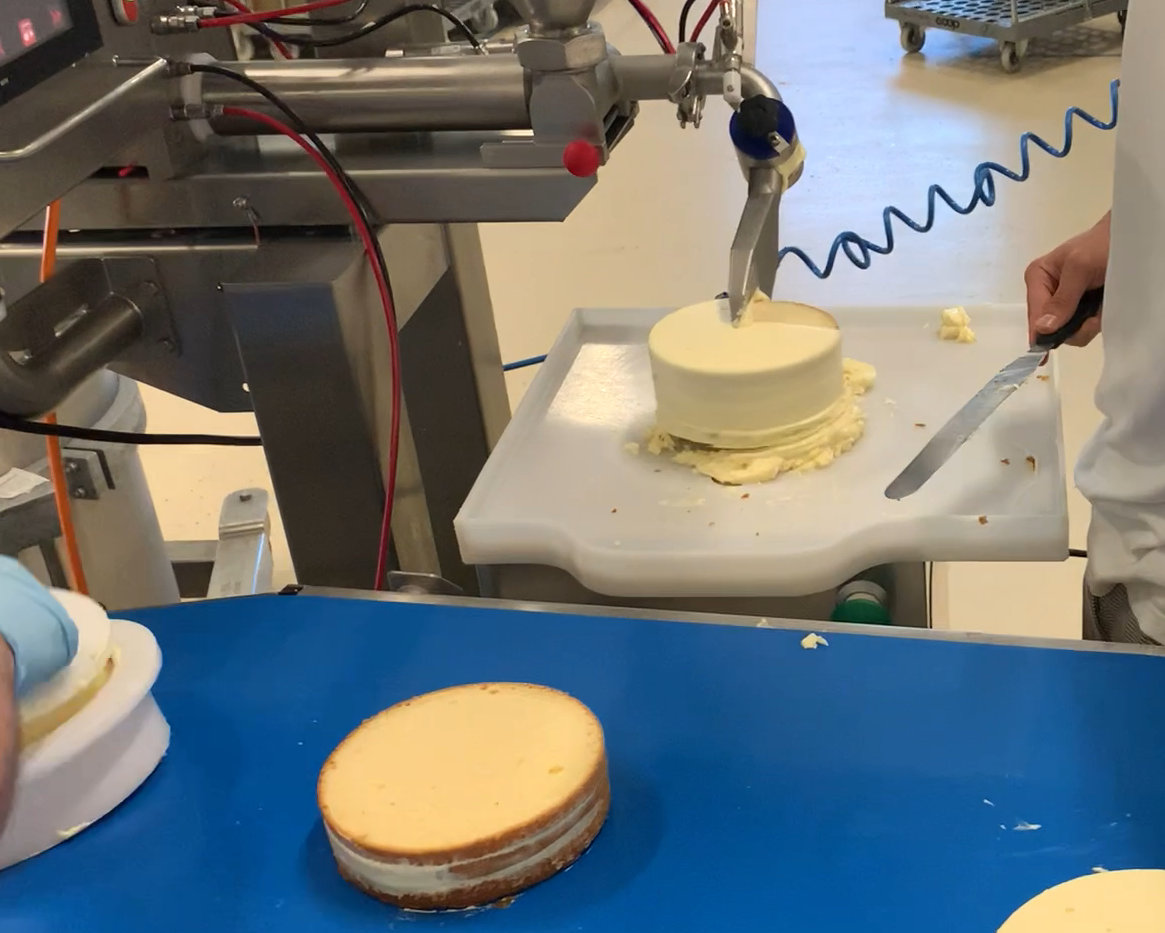

Process: The sponges are placed on the syrup spraying unit (1st person) where they are automatically detected and sprayed with syrup. The sponges move over to the conveyor of the Multi Station where the middle filing is applied automatically. Using a hopper divider can be an option when 2 different fillings have to be spread. The sponges move over onto the conveyor where they are assembled in a ring (2nd person). The top and side icing is done on the Cake-O-Matic (3rd person). Finally the finished cakes are put back onto the conveyor for decoration and packaging.

The complete production of the cakes is made in one step, from using the freshly baked sponges and fresh made cream right to putting the decorated cakes into packaging before they go into cooling or freezer. Fast, efficient and perfectly organized.

This production line can be used – thanks to the integrated Multi Station – for a wide variety of different applications and products!

Adding a second Cake-O-Matic would further increase the production capacity of this line from 700 up to 900 cakes/hour.

Capacity: up to 900 cakes/hour

Watch the Unifiller Cake Line in action

Good to know:

Thanks to the mobile frames with swivel castors and the small footprints the depositors can easily be moved around in the production area for different fields of application. Our customers enjoy the flexibility of their equipment! And there’re many accessories available for the Multi Station – for the realization of a wide range of different products! By changing the accessory of the Multi Station (change the middle filling nozzles against a straight spreader nozzle) the production of rectangular cakes can be realized, the set-up-time for the accessory switch is less than 5 minutes!

Easy Upgrades of the Cake Line:

- Add Hopper Topper pumps to fill your hoppers automatically

- Add a slicer for the sponges

- Add another Multi Station for different or more fillings (fruit fillings, cremes)

- Add a depositor for decorations along the conveyor

The Unifiller Cake Line

Starter Level

The Starter Level uses a Cake-O-Matic 1000i SV or a Cake Station for the middle filling of the cakes, instead of the Multi Station. When upgrading the line with the Multi Station later on, the existing Cake-O-Matic can be used for top- and side icing of the assembled cakes, that makes the line even faster!

Capacity: 400-450 cakes/hour

Production Process:

The sponge layers are put onto the Syrup Sprayer, where they’re automatically detected and sprayed. They’re carried onto the 5m conveyor. On the first Cake-O-Matic 1000i SV an employee applies the middle fillings onto the sponge layers. The layers are assembled and move ahead to the second Cake-O-Matic 1000i SV. Here the top & side icing is applied before the finished cakes go back onto the conveyor for decoration and packaging.

Easy Upgrades of the Cake Line:

- Add Hopper Topper pumps to fill your hoppers automatically

- Add a slicer for the sponges

- Add a depositor for decorations along the conveyor

Click here to learn more about our Systems for Cake Production

Are you interested to learn more about our solution for smaller industries producing up to 60 cakes per hour with just 1 employee? Click here to see our 1-Person-Cake-Line-Concept.

Please feel free to contact us for receiving further advice and information regarding our industrial Cake Lines and the possibilities they offer. Depending on our customers production needs, we will find the matching solution for everyone.

Get in

contact with us!

I'm pleased to answer any questions you may have.